News

Read the latest news from HydX

HydX Continues to Grow: Welcome Per Persson

HydX is pleased to welcome Per Persson to the role of Account Manager. With more than 30 years of experience in hydraulics, technical sales and system solutions, Per brings extensive expertise that further strengthens HydX’s customer offering.

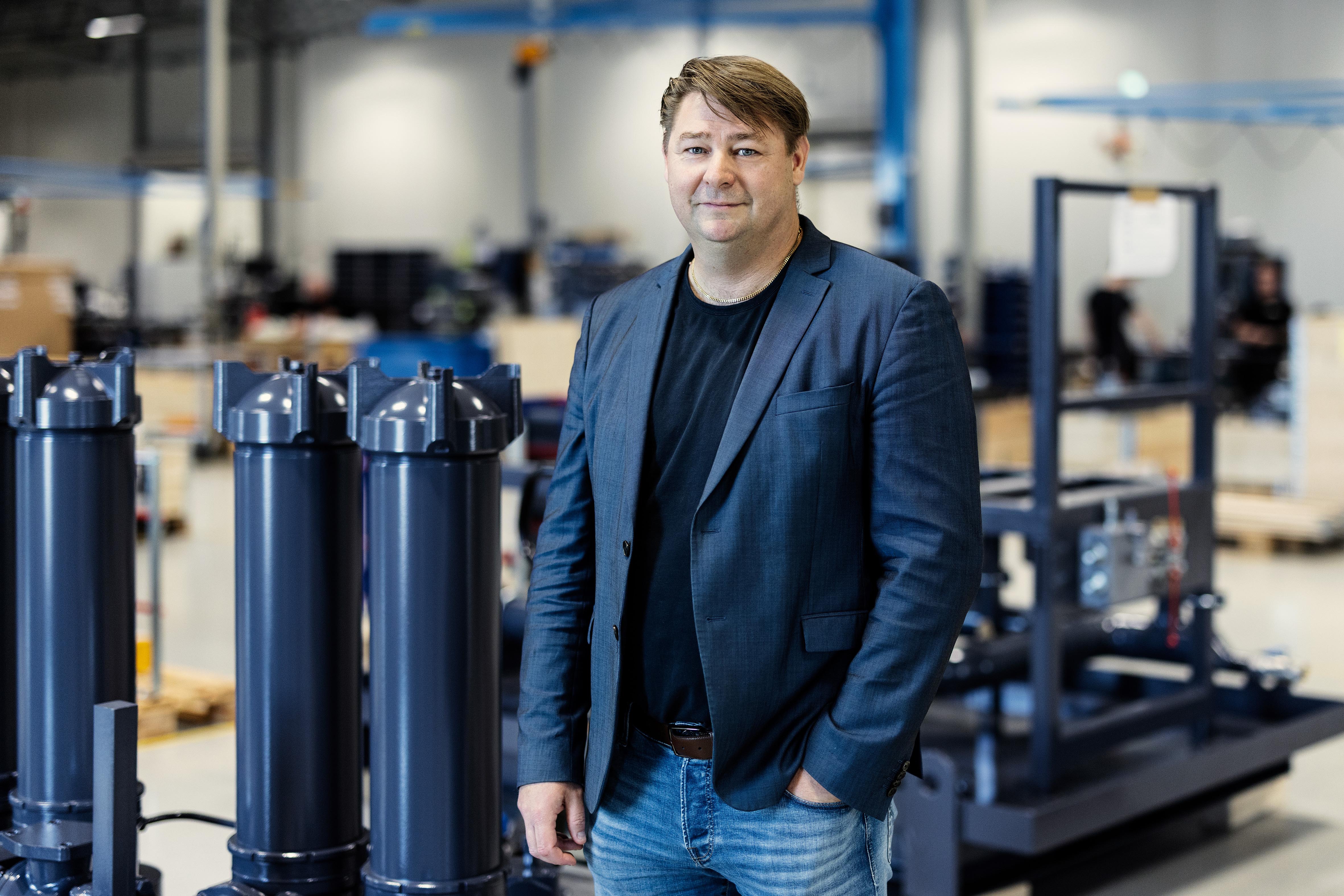

“At HydX, our core philosophy is to create real value for our customers”

From day-to-day operations to long-term strategic decisions, Mattias Salomonsson is involved in most parts of the business in his role as COO of HydX. In this interview, Mattias shares his view on HydX’s strategic direction and the priorities that will shape the company’s future.

Strong Performance in a Challenging Global Market

With Christmas and the New Year just around the corner, it is time to put another eventful year behind us. A year in which the world has continued to face uncertainty, while our own business has remained resilient. HydX enters 2026 with an even stronger organization, growing business, and a continued commitment to investing in future technologies. Our CEO, Mikael Andersson, shares his reflections on a year that challenged us - and ultimately made us stronger.

Philip Björk joins HydX!

We are pleased to present another new addition to our team. This time, it is Philip Björk, 28, who has been hired as a Design Engineer at the technical department in Ystad.

Management of Danfoss Power Solutions Visits HydX in Ystad

The management team of Danfoss Power Solutions and Volito Industry recently visited HydX’s newly constructed and environmentally certified facilities in Ystad. After many years of successful collaboration, the parties are now taking further steps to strengthen their partnership.

HydX Named Growth Distributor of the Year by Parker Hannifin

In 2024, HydX was recognised as the Nordic region’s first Certified Mobile Electrification Centre (CMEC) by Parker Hannifin. Now, the company has received yet another honour – HydX has been named Growth Distributor of the Year.

Tech Days – a Success Worth Repeating!

At Tech Days in Nordborg, Denmark, HydX and ETP are joining forces with Danfoss Power Solutions to explore the latest developments in electrification, IoT and hybrid solutions – and to exchange ideas on how technology can drive sustainability across industries.

Martin Fredriksson Strengthens HydX

We are pleased to welcome Martin Fredriksson, 43, to the HydX team. He joined on September 1 and brings with him extensive experience in hydraulics, control systems, electrification and programming.

New Talent at HydX

Last spring, Elis Andersson, 19, graduated from the T4 program at Ystad Gymnasium (Upper Secondary School), and shortly thereafter, he was hired by HydX, where he had also completed his internship.

Stay Connected – Follow or Get in Touch

With expertise in hydraulics, electronics and electrification, we deliver innovative and sustainable solutions for mobile, industrial and marine applications. Contact us to discuss your opportunities.

Contact & Staff

Subscribe to Our Newsletter